Pretreatment Filter

Conventional Water Filtration

- Sand filter

Pressure sand filters (PSF) are used in many industrial applications and often are popularly termed rapid sand bed filters. RPSF consists of a pressure vessel that is normally vertical or horizontal, in rare occasions, depending on the layout of the plant. The filter vessels are generally of welded mild steel construction lined with rubber/epoxy. A minimum of 50% freeboard is provided over the filtering bed depth to enable efficient backwash.

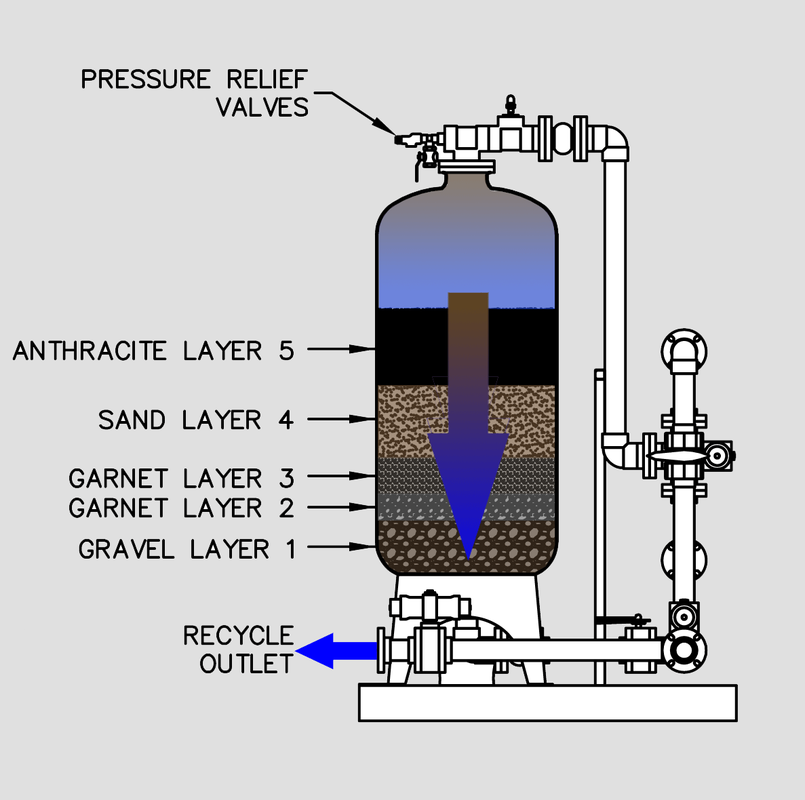

- Multimedia filter

Multi-media filter (MMF) based on the filter bed speed as input. For industrial water filtration purposes vertical filter bed speeds (ideal service flows) varying between 10 m/h and 25 m/h are used depending on the quality of the to be treated water. The higher the total suspended solids (TSS indicated in mg/l) content or the more turbid the water, the slower the vertical filter bed speed. Suspended solids consist of small particles such as silt, clay, grit, organic matter, algae and other microorganisms. Some advanced filtration media can still efficiently filter water at higher speeds, contact us for these applications. In private swimming pool water treatment filtration bed speeds of up to 50 m/hour are used. This is not recommended for industrial applications. Higher flow rates can prevent particles from adhering to the media granules or can dislodge particles that were previously retained. These filters are called multi-media filters because they contain different layers of filtration media ordered in decreasing porosity. Multi-media water filters are able to trap and retain a far larger number of particles (generally down to 10-25 microns) than traditional sand filters before backwashing becomes necessary.

- Carbon filter

- Softener filter

- De-Iron filter

The Iron Removal Filters are designed to remove the Excess Iron content present in the feed water with minimum pressure drop.

Most iron filtration systems operate on the principal of oxidizing the iron (oxidation) to convert it from a ferrous (dissolved or soluble) to a ferric or undissolved state. Once the iron is converted to ferric state, it is precipitated on a filter bed.

For low Iron content in feed water, the Filter consists of Manganese Zeolite, where the iron is oxidized to insoluble hydrated oxides that are removed by the mechanical filtering action of the Zeolite bed.

Advance Water Filtration

Microfiltration or Ultrafiltration is a type of physical filtration process where a contaminated fluid is passed through a special pore-sized membrane to separate microorganisms and suspended particles from process liquid. It is commonly used in conjunction with various other separation processes such as ultrafiltration and reverse osmosis to provide a product stream which is free of undesired contaminants.

Microfiltration usually serves as a pre-treatment for other separation processes such as ultrafiltration, and a post-treatment for granular media filtration. The typical particle size used for microfiltration ranges from about 0.1 to 10 µm.[1] In terms of approximate molecular weight these membranes can separate macromolecules of molecular weights generally less than 100,000 g/mol.[2] The filters used in the microfiltration process are specially designed to prevent particles such as, sediment, algae, protozoa or large bacteria from passing through a specially designed filter. More microscopic, atomic or ionic materials such as water (H2O), monovalent species such as Sodium (Na+) or Chloride (Cl−) ions, dissolved or natural organic matter, and small colloids and viruses will still be able to pass through the filter.

The suspended liquid is passed through at a relatively high velocity of around 1–3 m/s and at low to moderate pressures (around 100-400 kPa) parallel or tangential to the semi-permeable membrane in a sheet or tubular form.[4] A pump is commonly fitted onto the processing equipment to allow the liquid to pass through the membrane filter. There are also two pump configurations, either pressure driven or vacuum. A differential or regular pressure gauge is commonly attached to measure the pressure drop between the outlet and inlet streams.

The most abundant use of microfiltration membranes are in the water, beverage and bio-processing industries. The exit process stream after treatment using a micro-filter has a recovery rate which generally ranges to about 90-98 %.

-

Superpulsator® Clarifier The Superpulsator Clarifier combines basic chemical principles and proven clarification technology in a high-rate, solids contact clarifier that offers m...

- Reverse osmosis (RO) is a process that forces a feedwater stream containing dissolved impurities (salts and organics)through a semipermeable membrane into two separate st...

- Demineralization System Demineralized Water also known as Deionized Water, Water that has had its mineral ions removed. Mineral ions such as cations of sodium, calcium, iron, c...

- Bio Wastewater Treatment. Theactivated sludgeprocess is the most commonly applied biologicalwastewater treatmenttechnology. In this process, a bacterialbiomasssuspension (theactiva...